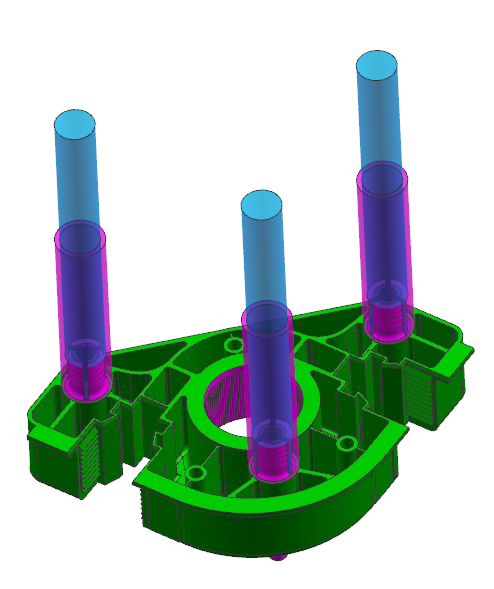

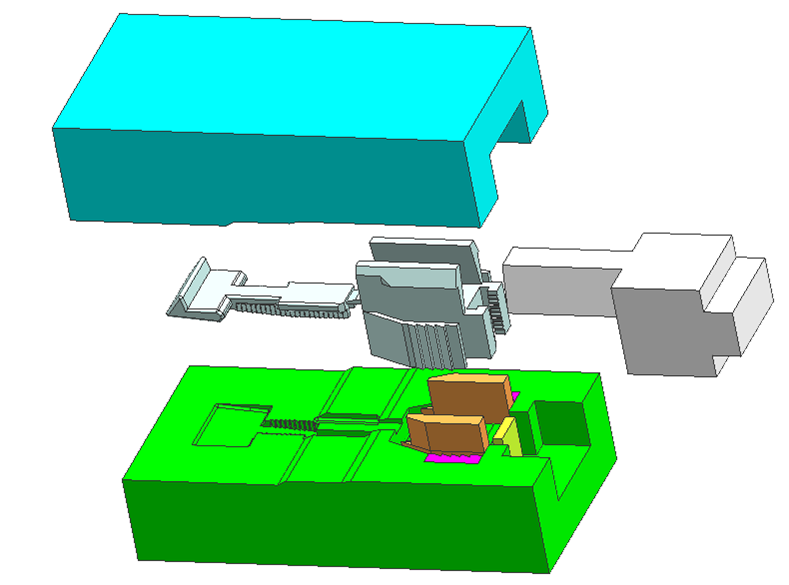

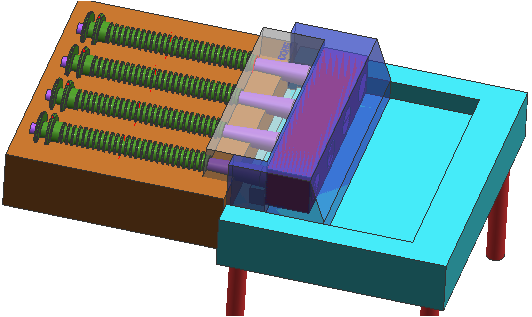

We believe quality begins with mould design capability and consider it to be the key to successful mould making. At Hoda Mould we have invested in both people and technology to ensure that our designs meet your highest expectations.

Our teams consists of 35 experienced mould designers utilizing the latest engineering software to directly take the clients CAD model into mould design. All mould designs are then validated to our clients tooling standards and moulding specifications.

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM’s (Electro-Discharge Machining)

9. Wire-Cut Machines.

Moulding materials

We have experience in the following materials:

Master batches are obtained from quality suppliers in the area thus minimizing problems in color matching. Pantone and RAL colors are available on request. All master batches are mixed in a sterile area with ample dust extraction to ensure no problems with spotting occur.

Hoda Mould operates a very flexible service on supplying smaller quantities of parts with assembly and finishing. All moulds manufactured by Hoda Mould and used in-house are free of any maintenance costs.